| Zootechnics cattle division |

| Systems and accessories for modern zootechnics |

|

|

|

| Cleaning systems |

|

|

|

Folding scrapers

Studied and built to reclaim spaces and prevents the dangerous smoothing of floorings.

Over 20 years experience gives us the knowledge to |

| develop these models in step with evolution of the environments in which they are installed. |

|

|

|

|

|

|

| Over the years, OMVE has installed over 1,000 scrapers ranging from 2 to 20 metres in width, throughout Europe, achieving first-class operational recognition. |

|

|

|

|

|

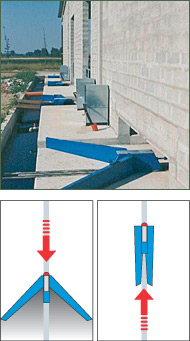

Butterfly scrapers

with articulated wings, ideal for passages without straw for farmed animals. On their return path, these scrapers close their “wings” in the middle avoiding any mobility problems for the animals. |

|

|

|

|

|

|

Scrapers for paddock passages

with pallets that raise automatically during the return phase, built for passages up to 17 metres. |

|

|

|

Eco scrapers

with mechanical trolley. |

|

|

|

|

|

|

Cable scrapers

during the unloading phase. |

|

|

|

|

|

|

|

|

|

Scrapers for rubber flooring.

The OMVE range also includes specific folding scrapers for rubber flooring equipped with the necessary technical devices for protecting the matting. |

|

|

|

|

|

|

|

|

|

| Folding scraper in the resting area. |

|

|

|

|

| Folding scraper during cleaning. |

|

|

|

|

| Folding scraper unloading in the tank. |

|

|

|

|

|

| R.A.S. Hidden unit with galvanised casing to position underneath the sliding surface of the scraper. |

|

R.S.V. Pulling unit with cylinder and guides in self-lubricating polystones. |

|

Oil-pressure unit for scrapers with automatic valve and electric motors up to 10 HP |

|

|

|