| Zootechnics cattle division |

| Systems and accessories for modern zootechnics |

|

|

|

| Free stabling cattlesheds |

|

|

|

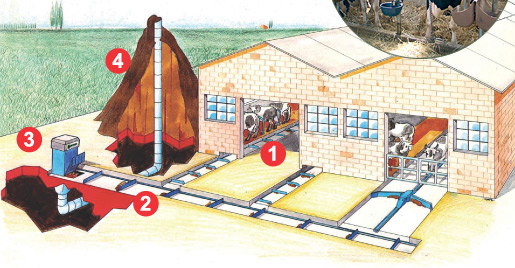

Manure accumulation oil-pressure system

model: vertical ”talpa” (mole)

manure removal system with oil-pressure press system, complete with unit from 7.5 HP or 10 HP

380/660 three-phase designed and inspected to resolve manure storage problems at a distance of approx. 50m from the collection and in low temperature conditions outside the stall. |

|

|

|

|

|

|

|

|

|

| 1 – Dung removal phase inside the stall by means of a channel in which the dung is conveyed by a rigid rod with blades, in steel or cast iron. |

|

|

|

|

| 2 – Oil-pressure pushing unit towards the “Talpa” (3). |

|

|

|

|

| 4 – Manure collection point equipped with ejection pipe, height 5m. |

|

|

|

|

|

Mod. EGN

Revolving elevator 180° for manure removal.

Conveyor length 6 - 8 - 10 metres |

|

|

|

|

|

Revolving closed circuit elevator.

Lengths up to 10 metres. |

|

|

|

|

|

|

| Mechanical propulsor unit on handling side. Model GPO Fitted with a galvanised inspection case, ideal for transferring manure in the stall up to 40m. |

|

| Motorization 2 and 3 CV. |

|

|

|

|

Oil-pressure manure pulling unit

model: GPI

Positioned sideways to

the channels

for belt

pulling, ideal

for lengths

up to

90m. |

|

|

|

|

Oil-pressure vertical “Talpa”.

By means of underground ducts, it pushes the dung towards the collection point situated up to a distance of 50m. |

|

|

|

|

|

|